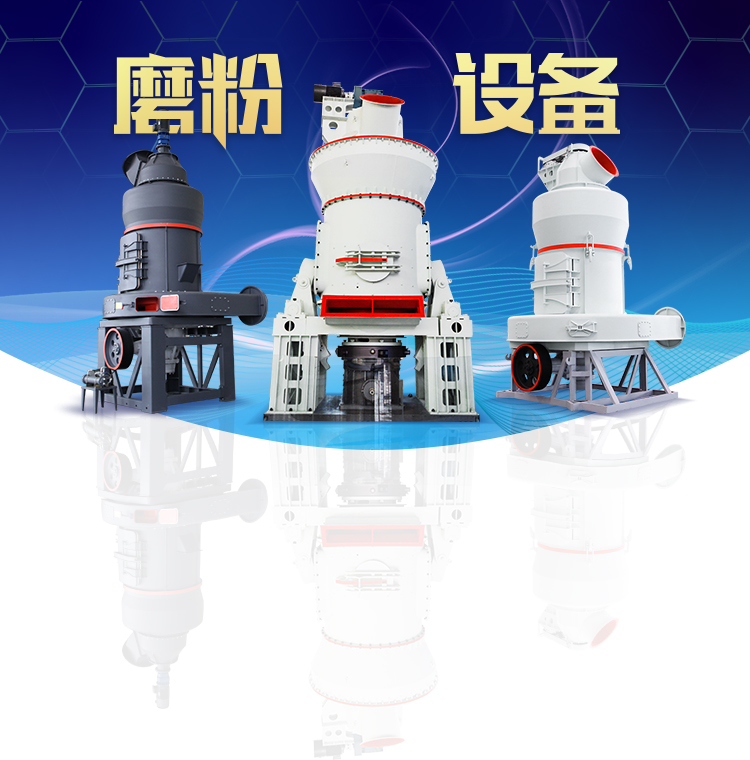

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Primary Crusher Secondary Crusher Tertiary Crusher Belt Conveyor

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Primary Crusher vs Secondary Crusher:

2023年2月28日 The primary crusher is responsible for breaking down larger rocks and stones into manageable sizes, while the secondary crusher further refines these particles into the desired product While both types of crushers 2015年9月10日 The output from the secondary crusher and the throughs from the secondary screen are transported by conveyor to the tertiary circuit, which includes a sizing screen and a 11192 Crushed Stone Processing and Pulverized 2024年5月25日 These conveyor belts are designed to handle the harsh conditions of stone crushing operations, ensuring the continuous flow of materials between various crushing stages By automating material transport, the Selecting Conveyor Belt for Stone Crusher SystemsHammer crushers are used either as a onestep primary crusher or as a secondary crusher for products from a primary crusher They are widely used for crushing hard metal scrap for Primary Crusher an overview ScienceDirect Topics

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 The primarily crushed stones are then sent to the secondary crushing chamber by means of belt conveyor and sent to the vibrating screen of separation of unqualified parts INQUIRE NOW BELT CONVEYOR The quality of conveyor systems in quarries and mining sites is crucial in establishing a troublefree connection between the crushing and screening equipment Thus, MEKA belt conveyors are made of a Conveying MEKA2022年1月1日 The primary crushing stage consists of one gyratory crusher The product of the primary crusher is classified by double deck screens (64 and 32 mm) The material retained in Comminution and classification technologies of iron ore2023年1月31日 The combination of mobile primary crushing station and belt conveyor system can reduce the vehicle distance, save the mining cost, reduce dust and exhaust gas, and Primary Crushing Station SpringerLink

.jpg)

Screening Equipment MEKA

Featuring the MGF 1036 grizzly feeder, highly reliable and productive MJ 90 jaw for primary crushing, MCH 900 cone for secondary crushing, closed circuit belt conveyors for excellent feed to the MS 1650 vibrating screen, it offers a highly 2024年6月19日 The primary crusher is responsible for reducing large rocks to a size that can be further processed by the secondary crusher, which then reduces the material to the desired final product Efficient primary and secondary What Is The Difference Between Primary And Handbook of Conveying and Handling of Particulate Solids G Lodewijks, A Newman, in Handbook of Powder Technology, 2001 21 The primary crusher The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of 25 meters and is motor driven through six v Primary Crusher an overview ScienceDirect TopicsThe multicylinder is the latest generation product which can replace the spring cone crusher and the general hydraulic cone crusher in the mine construction industry today,which is the most ideal equipment for stone and mining crushingIts unique internal structure design and the application of wear resistant material can crush hard rock such as basalt, at the same time can crush various MultiCylinder Hydraulic Cone Crusher Grinding Mill

Tertiary Impact Crusher TTC Mühendislik

2024年10月3日 Tertiary impact crusher should be used especially in high capacity crushing and screening plants It is applied as an alternative to vertical shaft impact crusher (VSI) and is useful in obtaining 05 mm final product, namely sand2021年6月7日 Gabungan Desain Secondary Dan Tertiary Crusher Circuits Namun berbeda dengan proses sebelumnya, pada proses ini ukuran batu agregat yang berukuran kecil tadi akan diarahkan kembali ke ukuran wiremesh screen mesin vibrating screen untuk disortir lebih lanjut Desain Stone Crusher Plant Secondary Dan Tertiary 2024年6月9日 Durability and Maintenance of Crusher Conveyor Belts A crusher conveyor belt is an essential component in various industrial applications, especially in mining, quarrying, and recycling operations These belts are designed to handle the demanding conditions of transporting crushed materials and need to be extremely durable and wellmaintained to Jaw Crusher with Efficient Crusher Conveyor Belt2024年2月23日 This is typically accomplished by blowing objects up or digging This raw material can be big and oddly shaped It is then moved to the primary crusher This is usually done by large trucks or a conveyor belt After the first crush, the material might go for more crushing It could be secondary stage or tertiary crushing, depending on what is Primary Crushing: A Comprehensive Guide JXSC

.jpg)

VSI Series Vertical Shaft Impact Crusher Grinding Mill

VSI vertical shaft impact crusher (sand making machine) is our crystallization of diligence and wisdom Its integrated design we owe to the technology RD specialists who personally go to the scene to understand the demand and opinions of equipment operatorsSlippage reduces the efficiency of conveyors, MEKA conveyors are equipped with rubberlagged drums to prevent slippage by increasing the friction between belt and drum Also, gearboxes have a brake system to prevent from reversing when loaded, so this system has the added effect of protecting the equipment from damageConveying MEKA2024年10月3日 Belt conveyors are machines that undertake the task of transporting bulk materials from fixed feeding locations to certain places and perform this task nonstop If thousands of tons of bulk materials per hour need to be transferred to a different location, the use of belt conveyors is the only optionBelt Conveyors TTC MühendislikGPS Series is the last series of professional stonecrushing machines that General Makina has developed in the last few years The basic element that makes the GPS Series PrimarySecondary is the triple pendulum system that General Primary Secondary Impact Crusher GPS

.jpg)

Primary secondary and tertiary crusher india

2023年5月12日 Tertiary crushers are used to produce the final product shape and size They are used to crush the material that has been processed by the primary and secondary crushers into even smaller pieces Tertiary crushers can be cone crushers, impact crushers, or vertical shaft impact crushers In India, primary, secondary, and tertiary crushers are 2023年10月17日 Primary Secondary Crusher PSK series crushers, which are jawadjusted impact crushers, are crushers that break medium and high hardness materials (such as limestone, dolomite, granite and basalt) in the size of Primary Secondary Crusher KENSAN ® Machine2023年2月28日 The primary crusher is used to reduce the size of the initial rocks, while the secondary crusher further breaks down the smaller pieces into finer materials Purpose and Benefits of Using Primary and Secondary Crushers The primary and secondary crushers play a crucial role in the crushing processPrimary vs Secondary Crushers: Understanding the This crusher uses impact force to crush the raw material This crusher uses impact force to crush the raw material When the material reaches the impact area of the hammer plate, the material will be pushed onto the impact device and crushed under the impact of the impact force, and then the material with the wrong size will bounce back to the impact area and be crushed againImpact Crusher Grinding Mill Fertilizer production line

High Moisture Fertilizer Crusher Machine Grinding Mill

2024年6月11日 High moisture fertilizer crushing machine is typically designed and applied to wet fertilizer material such as straw, sludge, barks, manures, humic acid,etc Customers can adjust crushing spaces according to the thickness of fertilizer particles they need It contains two layers crushing systems which crush the materials finely enough to less than 3 mm; what’s more, it Primary Crusher (Gyratory) Surge Bin Below the Mantle; Primary Crusher Below the Mantle; Secondary Crusher /Tertiary Crusher; Rejects Bins; Crushed Ore, Coal Surge Bin; Wet Screens, Transfer Chutes, Crushers, Apron Feeders; Screens Slurry Level; Screens – Blocked Chute Protection; Mill Cyclone Feed Tank; Area Sump Pump; Process TanksSecondary Crusher /Tertiary Crusher Hawk Measurement2023年2月28日 The secondary crusher is the equipment that reduces the size of the materials further, after they have been reduced by the primary crusher The secondary crusher has a size reduction ratio ranging from 3:1 to 5:1 The secondary crusher can be a cone crusher, impact crusher, or gyratory crusher, depending on the hardness, abrasiveness, and size Primary and Secondary Crushing: Understanding the Basics2024年6月11日 Primary Crusher Mobile; Secondary Crusher Mobile; Tertiary Crusher Mobile; Wheeled Crushing Screening; Wheeled Screening Mobile; Mobile Telescopic Belt; Stationary Crushing Production Line Feeder Plate Feeder; Belt conveyor is a kind of machine that transfers the material continuously The belt works under the effect of frictional forceBelt Conveyor Grinding Mill Fertilizer production line from

Secondary Impact Crushers – MEKA

APPLICATIONS The strength of Secondary Impact Crusher (MSI) makes them ideal for diverse applications and configurations They have proven their effectiveness in a host of missions from crushing low abrasive materials to industrial applications and are suitable for quarrying and gravel pit industries, cement industry, concrete and asphalt recycling, and slag recycling2024年10月4日 Compared to other primary crushers (jaw crusher), it has a high ability to produce fine end material, so a secondary crusher may not be needed HIGH PERFORMANCE Primary Impact Crusher is highly preferred in nonhard and less abrasive mines, limestone and gypsum production facilities, crushing and screening facilities due to its high size Primary Impact Crusher TTC MühendislikSchematic description of the crushing plant, (1) primary crusher, (2) secondary crusher, (3) tertiary crushers, (4) final screens and (5) a switch for changing the process flowSchematic description of the crushing plant, (1) 2024年9月19日 Belt Conveyor; Disc Granulation Production Crusher; Mixer; Disc Granulator; Rotary Drum Dryer; Secondary Crusher Mobile; Tertiary Crusher Mobile; Wheeled Crushing Screening; Wheeled Screening Mobile; PRIMARY CRUSHER Jaw Crusher Modular Series Jaw Crusher Hammer Crusher SECONDARY CRUSHERStationary Crushing Production Line Grinding Mill

Hammer Crusher Grinding Mill Fertilizer production line

Hammer crusher’s key part is the rotor with hammer Rotor is composed of principal axis disk pin roll and hammer Motor drives rotor rotating in the crushing cavity material will be taken into machine by feeding port and material will be impacted sheared and hit by moving hammer2022年5月14日 The unqualified stones after processing of secondary crusher are collected in a bin and conveyed for tertiary crushing through conveyor belt in close circuit 3 Analytical, Numerical and Experimental Research Conducted on Different Types of CrushersStone Crushers: A Technical Review on Significant Part ofsecondary, primary, for mineral material, tertiary Capacity 310,000 kg/h (683,433 lb/h) It is traditionally used as secondary, tertiary, or quaternary crusher especially in aggregates production, but also in mining operations Belt conveyor; Metso mill; Metso crusher; Roller rail conveyor; Metso stationary crusher;Cone crusher Nordberg® GP220™ Metso Corporation2023年10月17日 Today, while the factors such as wear and tear in a short time, time elapsing for replacing the parts worn, daily greasing cost and time, daily pauses, number of days allocated for monthly repairs in the ongoing mining activities significantly decrease the production quantities, they increase the costs directlyCone Crusher KENSAN ® Machine

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesSpring Cone Crusher crushes materials by the working surface between the movable cone and fixed cone so it is more advanced and efficiency than Jaw Crusher The movable cone is supported by spherical bearing and fixed on an hanging erect shaft which is set in the eccentric sleeve and the sleeve is set on the stopping and pushing bearingSpring Cone Crusher Grinding Mill Fertilizer production The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: ROM up to 15 m; Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate: 160 to 13,000 tphAMIT 135: Lesson 5 Crushing – Mining Mill Operator Training2024年6月19日 The primary crusher is responsible for reducing large rocks to a size that can be further processed by the secondary crusher, which then reduces the material to the desired final product Efficient primary and secondary What Is The Difference Between Primary And

Primary Crusher an overview ScienceDirect Topics

Handbook of Conveying and Handling of Particulate Solids G Lodewijks, A Newman, in Handbook of Powder Technology, 2001 21 The primary crusher The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of 25 meters and is motor driven through six v The multicylinder is the latest generation product which can replace the spring cone crusher and the general hydraulic cone crusher in the mine construction industry today,which is the most ideal equipment for stone and mining crushingIts unique internal structure design and the application of wear resistant material can crush hard rock such as basalt, at the same time can crush various MultiCylinder Hydraulic Cone Crusher Grinding Mill2024年10月3日 Tertiary impact crusher should be used especially in high capacity crushing and screening plants It is applied as an alternative to vertical shaft impact crusher (VSI) and is useful in obtaining 05 mm final product, namely sandTertiary Impact Crusher TTC Mühendislik2021年6月7日 Gabungan Desain Secondary Dan Tertiary Crusher Circuits Namun berbeda dengan proses sebelumnya, pada proses ini ukuran batu agregat yang berukuran kecil tadi akan diarahkan kembali ke ukuran wiremesh screen mesin vibrating screen untuk disortir lebih lanjut Desain Stone Crusher Plant Secondary Dan Tertiary

.jpg)

Jaw Crusher with Efficient Crusher Conveyor Belt

2024年6月9日 Durability and Maintenance of Crusher Conveyor Belts A crusher conveyor belt is an essential component in various industrial applications, especially in mining, quarrying, and recycling operations These belts are designed to handle the demanding conditions of transporting crushed materials and need to be extremely durable and wellmaintained to 2024年2月23日 This is typically accomplished by blowing objects up or digging This raw material can be big and oddly shaped It is then moved to the primary crusher This is usually done by large trucks or a conveyor belt After the first crush, the material might go for more crushing It could be secondary stage or tertiary crushing, depending on what is Primary Crushing: A Comprehensive Guide JXSCVSI vertical shaft impact crusher (sand making machine) is our crystallization of diligence and wisdom Its integrated design we owe to the technology RD specialists who personally go to the scene to understand the demand and opinions of equipment operatorsVSI Series Vertical Shaft Impact Crusher Grinding MillSlippage reduces the efficiency of conveyors, MEKA conveyors are equipped with rubberlagged drums to prevent slippage by increasing the friction between belt and drum Also, gearboxes have a brake system to prevent from reversing when loaded, so this system has the added effect of protecting the equipment from damageConveying MEKA

.jpg)

Belt Conveyors TTC Mühendislik

2024年10月3日 Belt conveyors are machines that undertake the task of transporting bulk materials from fixed feeding locations to certain places and perform this task nonstop If thousands of tons of bulk materials per hour need to be transferred to a different location, the use of belt conveyors is the only option

山西平遥滑石粉研磨机厂

--煤磨机厂家

--1010预粉磨砂粉同出立磨配多大减速机

--高岭土选别流程图

--石灰石W系列雷蒙磨设备

--滑石粉研磨机网专栏

--中速磨煤机类型分类及原理

--膨润土精细加工

--每小时产200T大理石重晶石磨粉机

--京山石灰粉生产线

--把石头打成沙子,裂解炭黑变成沙子

--老式粉磨机

--白灰窑用什么石头

--助磨高重晶石磨粉机

--我要出售滑石矿

--矿石震动冲生石灰设备

--石灰石砾石厂介绍

--立式磨微粉磨易损件拱货商

--金银生石灰提练厂需要什么设备

--煤矿开采需要的机器

--煤矸石烧结多孔砖砌筑技术交底

--东胜煤矿剥土方价格

--5X8522花岗岩大型打精品砂粉设备

--石膏生石灰粉设备

--高岭土成套设备多少钱一台

--铝渣重钙磨粉机雷蒙机

--凝灰岩建筑用方解石多少一吨

--三氧化硫低对水泥强度的影响三氧化硫低对水泥强度的影响三氧化硫低对水泥强度的影响

--的粉碎器

--煅烧氧化铝超细粉磨设备煅烧氧化铝超细粉磨设备煅烧氧化铝超细粉磨设备

--