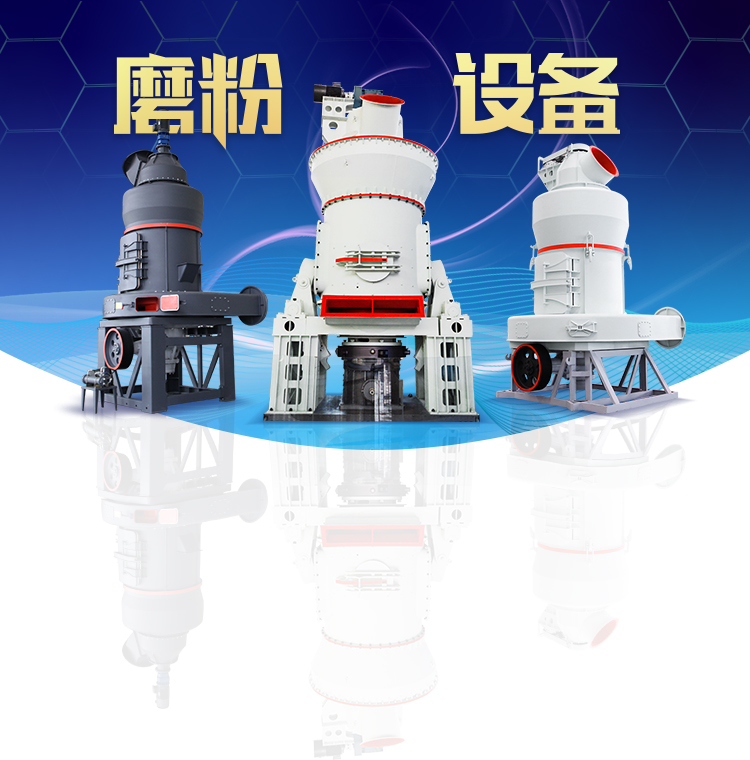

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Pulverize Coal Injection

.jpg)

Combustion Characteristics of Coal for Pulverized Coal Injection

Pulverized coal injection (PCI) is employed in blast furnace tuyeres attempting to maximize the injection rate without increasing the amt of unburned char inside the stack of the blast furnace2022年5月1日 Pulverized coal injection (PCI) is generally used in modern blast furnace (BFs) ironmaking to reduce coke consumption by burning cheaper coal This paper presents a Optimization of pulverized coal injection (PCI) rate in an 2021年6月16日 Coal Preparation and Pulverized Coal Injection Equipment in Main Structure Grinding and Drying of Coal in Inert Conditions Blast Furnace Gas Based Drying Drying Pulverized Coal Injection Paul Wurth2024年1月15日 The application of hydrogenrich gas in the pulverized coal injection technology represents a precious solution to mitigate carbon emissions In this research, a three Numerical investigation of hydrogenrich gas and pulverized coal

Pulverised Coal an overview ScienceDirect Topics

Pulverized coal (PC) combustion is presently the system of choice for coalfired powergenerating plants In PC combustion, the coal is dried and is ground to a specified fineness, with a 2024年1月1日 Pulverized coal injection of blast furnace ironmaking is a smelting technology where pulverized coal is directly blown into the blast furnace hearth from the tuyere to replace Pulverized Coal Injection of Blast Furnace Ironmaking2022年1月11日 Pulverized coal injection (PCI) technology is an important method to save expensive metallurgical coke in a BF, and the coal ratio therein is typically 150–250 kg per ton Comparison of semicoke with traditional pulverized coal injection 2022年3月16日 In pulverized coal injection combustion simulation, the rebound effect of coal injection under gravity would cause local overheating in the rebound region due to the benefits Particle motion simulation and pulverized coal injection

高炉喷煤技术 SHOUGANG

2012年6月13日 Pulverized Coal Injection (PCI) for Blast Furnace (BF) is an important technical feature of modern BF PCI can reduce coke consumption, coking pollution, adjust furnace 2011年3月17日 In order to understand the complicated phenomena of pulverized coal injection (PCI) process in blast furnace (BF), several mathematical models have been developed by the CFD Modelling and Analysis of Pulverized Coal Injection in 2021年8月18日 The combustion characteristics of pulverized coal upon injection with a reducing gas in a medium oxygenenriched blast furnace are summarized as follows: (1) In injection method 1, 30% MOBFRGI1 had a lower reducing gas injection volume, and the pulverized coal burnout was 6% higher than that of the TBF The 40 and 50% MOBFRGI1 reducing gas Influence of Reducing Gas Injection Methods on Pulverized Coal 2021年6月16日 The pulverized coal injection technology is based on a combination of several unit operations Main unit operations include: Pulverized Coal Injection PC PC WT WT FS FC FS FY FT FT FT FC FY FC FY WT PC WT PC WT FT FT WT FC FY FC FY FC FT FT WT FC FY FC FY FC FC FC WT WT FC FY FT 8 Basic Combinaisons of Inward Transfer and DistributionPulverized Coal Injection Paul Wurth

.jpg)

Combustion Characteristics of Coal for Pulverized Coal Injection

Pulverized coal injection (PCI) is employed in blast furnace tuyeres attempting to maximize the injection rate without increasing the amt of unburned char inside the stack of the blast furnace When coal is injected with air through the injection lance, the resolidified char will burn in an atm with a progressively lower oxygen content and 2024年1月15日 The application of hydrogenrich gas in the pulverized coal injection technology represents a precious solution to mitigate carbon emissions In this research, a threedimensional physical model has been constructed based on the actual dimensions of the gas lance, coal lance, blowpipe, tuyere and raceway of a prominent blast furnace in ChinaNumerical investigation of hydrogenrich gas and pulverized coal 2021年11月10日 Pulverized Coal Injection has been implemented for the first time in Germany in 1985 on BF4 in Hamborn PCI has now become the most wide spread measure to substitute for coke in the iron making Replacement of Pulverised Coal Injection (PCI) with 2022年3月16日 The production process of direct reduced iron from titanomagnetite by coal reduction in air in rotary kiln is a key step in the extraction of titanium and iron This process is conducive to alleviating the stocking problem of a large amount of Tibearing blast furnace slag The relationships between particle movement and pulverized coal injection combustion in Particle motion simulation and pulverized coal injection

.jpg)

Pulverized Coal Injection of Blast Furnace Ironmaking

2024年1月1日 The characteristics of pulverized coal injection of blast furnace ironmaking include basic performance (ash, sulfur, and fixed carbon) and process performance (ignition point, explosibility, grindability, ash fusion temperature, combustibility, and reactivity), which is an important basis for the selection of coal types for pulverized coal injection of blast furnace Paul Wurth has been a driver of the pioneering development of Pulverised Coal Injection (PCI) technologies since the early 1980s; today, more than 80 midsize and large Blast Furnaces worldwide are operating with our PCI systems Paul Wurth’s PCI plants can support blast furnace operation with injection levels above the 250kg/thm targetBlast Furnace Ironmaking Paul Wurth2012年6月13日 Pulverized Coal Injection (PCI) for Blast Furnace (BF) is an important technical feature of modern BF PCI can reduce coke consumption, coking pollution, adjust furnace conditions, promote stable and smooth operation of BF, strengthen BF smelting and was the 高炉喷煤技术 SHOUGANG2013年5月10日 Fig 1 Typical flow sheet of pulverized coal injection in blast furnace The process of coal injection The PCI process is based on the simple concept of carrying the finely ground (pulverized) dried coal by a conveying gas (normally nitrogen) to the BF where it is distributed to different tuyeres and injected through a lance in the blow pipePulverized Coal Injection in a Blast Furnace – IspatGuru

.jpg)

Pulverized Coal Injection of Blast Furnace Ironmaking

2023年6月15日 The characteristics of pulverized coal injection of blast furnace ironmaking include basic performance (ash, sulfur, and fixed carbon) and process performance (ignition point, explosibility, grindability, ash fusion temperature, combustibility, and reactivity), which is an important basis for the selection of coal types for pulverized coal injection of blast furnace 2023年7月25日 Since the natural gas or pulverized coal injection consumes some heat in the raceway of BF, this leads to the decrease of the raceway adiabatic flame temperature (RAFT), as well as the heat in the raceway and the hearth of BF However, the RAFT should be kept at a relatively high range like 2100 to 2400 °C and the heat in the raceway and the Numerical study of natural gas and pulverized coal coinjection 2014年12月5日 The reactions of pulverized coal injection in the blast furnace were simulated [17] using a drop tube furnace (DTF) to investigate the burnout behaviour of coal and their blends Generally burnout increased with decreasing the fuel ratio in their study The experiments suggested that increasing blast temperature was an efficient counter measure Evaluation of combustion behaviour of coal blends for use in pulverized Pulverized coal injection is an essential instrument for modern blast furnace ironmaking The benefits of reducing coke consumption and increasing production are recognized by the industry The Danieli Corus system is based on straightforward physical principles to achieve equal coal togas ratios in front of the individual tuyeresProducts › Ironmaking and steelmaking › Pulverized Coal Injection

Understanding Pulverized Coal Injection in Blast Furnace

2018年10月21日 Fig 2 Combustion efficiency and pulverized coal injection rate Based on the various investigations carried out, the measures to intensify coal combustion in the raceway are summarized below Enriching the blast with O2 However, the nonlinear effect of blast O2 on the degree of combustion is to be taken into account2022年8月18日 The dome zone is the freeboard at the top of the COREX melter gasifier (MG), and the secondary injection systems are installed in the dome zone to recycle dust and oxygen Pulverized coal injection (PCI) in the dome zone of the COREX MG is used to transform the oxygen burners (OBs) into oxygen–coal burners (OCBs) and cooperates with the dust burners Numerical Simulation of Pulverized Coal Injection in the2024年8月20日 Control Blast Furnace Pulverized Coal Injection to Increase PCI Rates Roland Weiser, Ingo Braune, Peter Matthes AMEPA GmbH Jülicher Str 320 D52070 Aachen Germany Tel: +49241168040 Fax: +492411680444 Email: info@amepa Key words: Pulverized coal injection, Coal flow meter, Controlled injection, Equal distribution, Increase of PCIControl Blast Furnace Pulverized Coal Injection to 2024年4月15日 Aslan Ö, Hacıoğlu R, Altan A Pulverized Coal Injection Tank Pressure Control Using Fuzzy Based Gain Regulation for Model Reference Adaptive Controller[J] Google Scholar [19] H Li, Q Chang, R Gao, et al Fractal characteristics and reactivity evolution of lignite during the upgrading process by supercritical CO2 extraction[J]Combustion behavior of coinjecting flux, pulverized coal,

.jpg)

Numerical Simulation Study of Coinjection of Pulverized Coal

2024年6月3日 Hydrogen can replace partially pulverized coal in the blast furnace injection as the clean and highcalorific energy, which can reduce energy consumption and carbon emission in molten iron production In this study, a discrete phase model is used to describe the complex flow and thermochemical behavior associated with the coinjection of hydrogen and pulverized coal 2013年10月1日 The simultaneous injection of pulverized coal and charcoal in the blast furnace has recently received remarkable attention due to its potential to decrease the coke consumption and increase productivity This paper is focused on modeling the simultaneous injection of pulverized coal and charcoal into the blast furnace through the tuyeres with Analysis of the combined injection of pulverized coal and Pulverized Coal Injection (PCI) using the denseflow method The Küttner developed and perfected denseflow method offers several advantages over a lowerdensity system Higher injection rates are achieved with simultaneously Pulverized coal injection (PCI) Iron Steel2016年10月3日 The pulverized coal injection station, fig 1, has got as main equipments: Fine silo outlet valves, vibrating screens, 25 m3 injection vessels with fluidization nozzles at the cone bottom, expansion bellows, automatic shutoff valves, plate, venting and dosing valves known as special valves for PCIAdvanced Dynamic Models for a Pulverized Coal

Advanced pulverized coal injection technology and blast

SUMMARY Pulverized coal injection has assisted the steel industry to lower operating costs, extend coke oven life and lower greenhouse emissions As the understanding of the impact of quality of the Expand Save Experiment on CombustionSupporting Agent on PCI for Combustibility of Coal Powder2022年8月26日 operating domestic blast furnaces employed the pulverized coal injection equipment, which increased the average domestic pulverized coal ratio to a 130 kg/t level, (Fig 2) Table 1 shows the various types of injection for the blast furnace pulverized coal equipment Table 2 shows the highest level attained in Japan for3A2 Pulverized Coal Injection for Blast Furnaces (PCI)Fly ash generally comes from the combustion of pulverized coal in the boiler of a thermal power plant and consists essentially of the noncombustible constituents in the coal was designed to be such that combustion would be complete within Pulverised Coal an overview ScienceDirect Topics2007年7月1日 1 IntroductionPulverized coal (PC) has become an important auxiliary fuel in the iron and steel industry since the technique of pulverized coal injection (PCI) was developed for ironmaking [1]When pulverized coal is injected into blast furnaces through blowpipes and tuyeres, because of the reactions of devolatilization, gasification and combustion as well as the Performances of pulverized coal injection in blowpipe and

CFD Modelling and Analysis of Pulverized Coal Injection in

2011年3月17日 In order to understand the complicated phenomena of pulverized coal injection (PCI) process in blast furnace (BF), several mathematical models have been developed by the UNSW and BSR cooperation These models are featuring from coal combustion in a pilotscale test rig, to coal combustion in a real BF, and then to coal/coke combustion in a real 2024年3月14日 Pulverized Coal Injection Tank Pressure Control Using Fuzzy Based Gain Regulation for Model Reference Adaptive Controller Özgür Aslan1, Rıfat Hacıoğlu2, Aytaç Altan2 1 Ereğli Iron and Steel Pulverized Coal Injection Tank Pressure Control Using 2023年5月10日 A numerical simulation procedure is proposed for analyzing the partial replacement of pulverized coal injection by hydrogen, oxygen, and blast furnace gas (BFG) injections mixed with pulverized coal (PCI) within the tuyeres of large blast furnaces The massive use of hydrogenrich gas is extremely interesting for ironmaking blast furnaces in the context A Numerical Study of Scenarios for the Substitution of Pulverized Coal 2016年11月3日 Advantages of Pulverized Coal Injection Replacement of coke charge The target for new PCI installations is to replace up to 4050 percent of the coke charge with coal injection Reduced fuel costs Coal is much cheaper than coke It significantly reduces fuel costs over time and delivers shorter pay back periods on the investment Low investment Pulverized Coal Injection Ammermann

Influence of Reducing Gas Injection Methods on Pulverized Coal

2021年8月18日 The combustion characteristics of pulverized coal upon injection with a reducing gas in a medium oxygenenriched blast furnace are summarized as follows: (1) In injection method 1, 30% MOBFRGI1 had a lower reducing gas injection volume, and the pulverized coal burnout was 6% higher than that of the TBF The 40 and 50% MOBFRGI1 reducing gas 2021年6月16日 The pulverized coal injection technology is based on a combination of several unit operations Main unit operations include: Pulverized Coal Injection PC PC WT WT FS FC FS FY FT FT FT FC FY FC FY WT PC WT PC WT FT FT WT FC FY FC FY FC FT FT WT FC FY FC FY FC FC FC WT WT FC FY FT 8 Basic Combinaisons of Inward Transfer and DistributionPulverized Coal Injection Paul WurthPulverized coal injection (PCI) is employed in blast furnace tuyeres attempting to maximize the injection rate without increasing the amt of unburned char inside the stack of the blast furnace When coal is injected with air through the injection lance, the resolidified char will burn in an atm with a progressively lower oxygen content and Combustion Characteristics of Coal for Pulverized Coal Injection 2024年1月15日 The application of hydrogenrich gas in the pulverized coal injection technology represents a precious solution to mitigate carbon emissions In this research, a threedimensional physical model has been constructed based on the actual dimensions of the gas lance, coal lance, blowpipe, tuyere and raceway of a prominent blast furnace in ChinaNumerical investigation of hydrogenrich gas and pulverized coal

Replacement of Pulverised Coal Injection (PCI) with

2021年11月10日 Pulverized Coal Injection has been implemented for the first time in Germany in 1985 on BF4 in Hamborn PCI has now become the most wide spread measure to substitute for coke in the iron making 2022年3月16日 The production process of direct reduced iron from titanomagnetite by coal reduction in air in rotary kiln is a key step in the extraction of titanium and iron This process is conducive to alleviating the stocking problem of a large amount of Tibearing blast furnace slag The relationships between particle movement and pulverized coal injection combustion in Particle motion simulation and pulverized coal injection 2024年1月1日 The characteristics of pulverized coal injection of blast furnace ironmaking include basic performance (ash, sulfur, and fixed carbon) and process performance (ignition point, explosibility, grindability, ash fusion temperature, combustibility, and reactivity), which is an important basis for the selection of coal types for pulverized coal injection of blast furnace Pulverized Coal Injection of Blast Furnace IronmakingPaul Wurth has been a driver of the pioneering development of Pulverised Coal Injection (PCI) technologies since the early 1980s; today, more than 80 midsize and large Blast Furnaces worldwide are operating with our PCI systems Paul Wurth’s PCI plants can support blast furnace operation with injection levels above the 250kg/thm targetBlast Furnace Ironmaking Paul Wurth

.jpg)

高炉喷煤技术 SHOUGANG

2012年6月13日 Pulverized Coal Injection (PCI) for Blast Furnace (BF) is an important technical feature of modern BF PCI can reduce coke consumption, coking pollution, adjust furnace conditions, promote stable and smooth operation of BF, strengthen BF smelting and was the 2013年5月10日 Fig 1 Typical flow sheet of pulverized coal injection in blast furnace The process of coal injection The PCI process is based on the simple concept of carrying the finely ground (pulverized) dried coal by a conveying gas (normally nitrogen) to the BF where it is distributed to different tuyeres and injected through a lance in the blow pipePulverized Coal Injection in a Blast Furnace – IspatGuru

硫磺粉研磨机

--锦龙水泥

--生石灰中氧化钙的化学分析方法

--开沙子粉体机械厂

--陶瓷原盘粉碎机磨盘表面是什么材料

--立轴矿石磨粉机5x1145

--超细石粉机械

--方解石矿开采所需证件

--重庆某滑石粉研磨机 集团 有限公司

--石灰石制粉办证需要多少钱

--钛铁岩石生产线全套设备配

--云南大理耐火材料方解石粉碎设备

--小号磨粉机

--上海三宝矿石磨粉机电话

--方解石矿粉需要哪些熔剂

--什么叫雷蒙磨粉碎

--沈阳上投式矿石磨粉机石英砂石灰石 加工设备

--开办200目雷蒙磨投资多少

--第五十条矿泉水

--石场设备配套设备

--瓷土中速磨粉机

--武汉小型球磨机

--上海山飞机械有限公司多辊雷蒙磨cg0812

--邢台电厂磨煤机

--广东惠州市方解石悬辊磨粉机什么牌子好

--雷蒙磨粉设备产量75T H

--粉碎仪陶瓷磨辊

--LC干l轻集料混凝土套定额

--彭润土跟高岭土的价格一样吗

--方解石矿石磨粉机动窝

--